Mechanical thermostats are rapidly becoming obsolete. When you consider that replacing a thermostat with a 4 – 6°F differential between on and off with an electronic controller having a 2°F differential, the savings in energy are significant. The heater shuts off much sooner, which results in a lower heat loss from the greenhouse surface and an energy savings.

For example, if we assume a 30’ x 100’ double covered greenhouse in a northern climate (Hartford CT) heated to a night temperature of 60°F during the winter, replacing the mechanical thermostat having a differential of 6°F with a controller having a 2°F differential will result in a savings of about 750 gallons of fuel oil. Instead of heating the greenhouse air to 66°F before the heater shuts off, the controller will shut the heater off at 62°F. For each degree that the temperature in the greenhouse can be lowered, there is an approximate 3% savings in fuel. At today’s energy prices, the payback for installing the controller is less than one year.

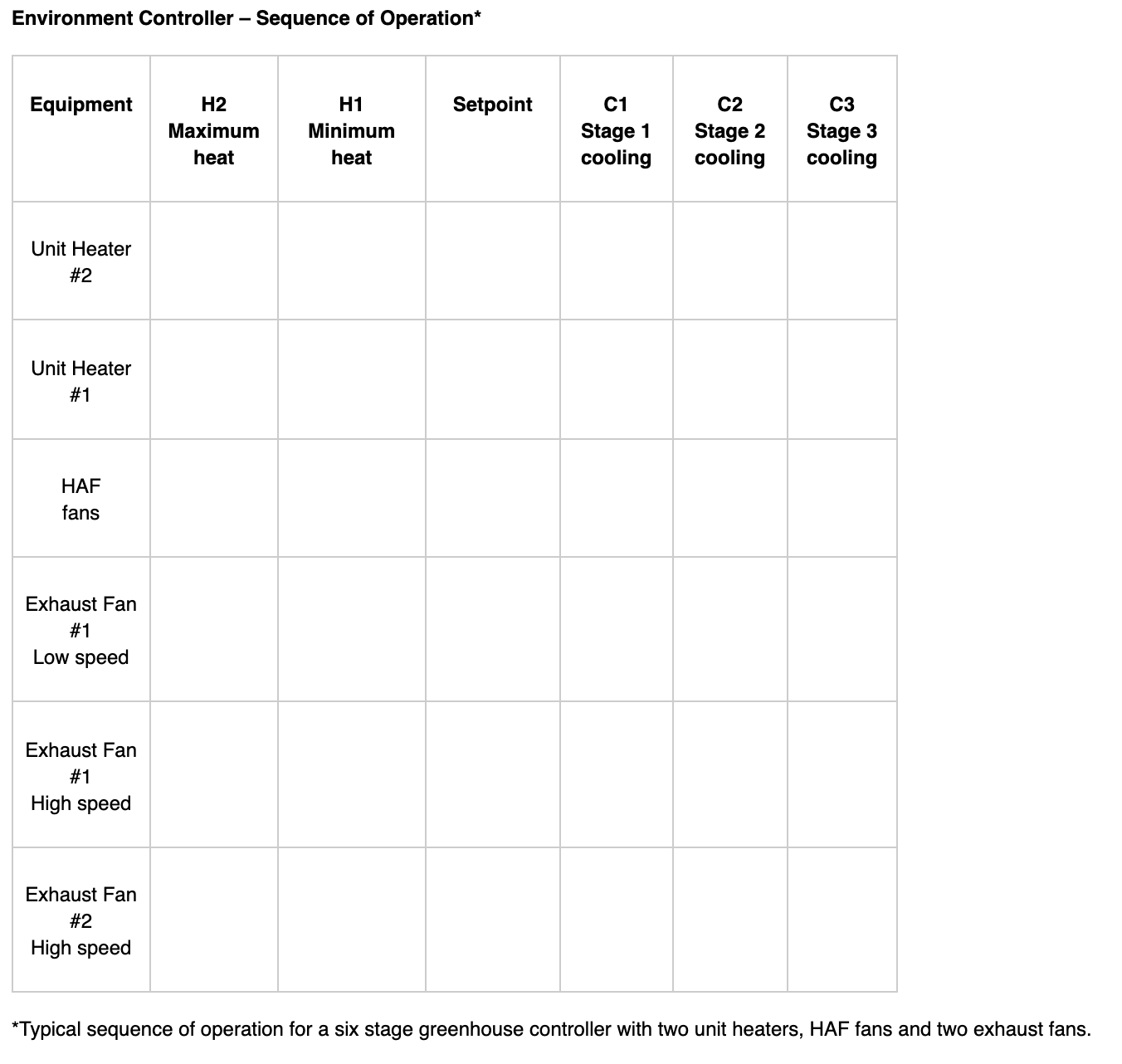

A programmable controller is a control device that has a logic potential but is not powerful enough to be called a computer. The simplest ones replace several thermostats and usually have 5 to 6 stages of control (two heat stages and 3 or 4 cooling stages plus a setpoint).

Step controllers use a solid-state integrated circuit to monitor environmental data in the greenhouse and create output signals that activate equipment based on a set of internal programmed instructions. The microprocessor is a simple, low-cost device that is reliable, accurate and works well in a greenhouse environment. Cost for basic step controllers usually runs from $600 to $1500 depending on the number of steps and relays or contactors that are needed to control the equipment.

Controller advantages include:

- The heating and cooling functions of the greenhouse are divided into stages and the controller steps between stages as conditions in the greenhouse change. Multiple pieces of equipment can be assigned to each stage, such as two heaters, HAF fans and an energy screen at stage 2. The sequence of equipment operation and the temperature at each stage is programmed by the grower.

- All components are located in one waterproof enclosure, reducing moisture, dust and maintenance.

- Installation time is reduced as relays, switches and controls are prewired.

- The sensor is remote and can be located among the plants while the control box is out of the plant zone.

- Energy use is reduced due to more accurate sensing and control.

Controllers operate with a setpoint, the air temperature that you would like in the greenhouse. If the temperature falls below the setpoint, the heating system will be activated. If the temperature exceeds the setpoint, the vents will open or the fans will activate, providing cool air. With multiple cooling stages, a different setting on the vents or additional fans will start. A final stage could include the activation of an evaporative cooling system. An override is provided at each stage for manual operation.

The following features or functions may be standard or optional depending on the manufacturer and model:

- LED screen – Displays the current temperature, time, date and other information.

- Battery backup – Stores the settings in case of power failure.

- Alarm activation – Can be connected to a trouble alarm.

- Ramping – Controls the rate of change between day and night settings.

- Temperature sensitivity – Accuracy should be between 1/2° to 1°F for best control.

- Temperature difference between stages – May be fixed or variable

- Day-night temperature setting – Most manufacturers use a light sensor to detect the graying of the sky at sunrise or sunset. This can usually adjusted for light level.

- Programmable night cooling lockout – Can disable one or more ventilation stages after dark.

- Aspirated sensor box – Includes a small fan that draws air over the sensors to obtain an average temperature in the greenhouse.

- Tracking – Data storage of high/low temperature for each setpoint. Storage of data up to 7 days. Some units have software to allow connection to a personal computer.

Advanced controllers offer many of the above features plus additional stages of control, input from a weather station and the ability to control multiple zones.

The above describes the typical temperature controller. There have been many specialized controllers developed during the past few years that control other greenhouse equipment.

- Ventilation controller – this unit is usually designed to provide control of roof vents, side vents, roll up walls and retractable roofs. It provides operation in multiple stages or settings.

- Irrigation and misting controller – A unit to control solenoid valves that automate the watering system. Activation can be based on soil moisture or vapor pressure deficit and time of day. Multiple zones can be controlled.

- Energy/shade screen system controller – Designed to open and close screens either automatically with a light sensor. Usually includes safety features that protect the motor and screen from overload.

- Demand shedding controller – When the controller senses that the electrical demand is approaching a critical level, the unit shuts off equipment to keep the demand below that level.

- Boiler controller – This device senses carbon dioxide and oxygen levels of the flue gases and adjusts the combustion air intake to yield optimum combustion efficiency.

USDA NRCS and some state and utility energy programs have grants that pay up to 75% of the cost of more efficient control systems. A good website to view for grant programs is www.dsireusa.org.

Controllers are the next level of control above thermostats and time clocks. They have proven to provide better environment control while at the same time saving energy.

John W. Bartok, Jr., Extension Professor Emeritus & Agricultural Engineer, Department of Natural Resources and the Environment, University of Connecticut, Storrs CT – Updated 2013.