The trend toward restricting herbicide use has produced interest in alternative and integrated weed control strategies that include cultivation. As a result, implements are now available to vegetable growers, but the potential uses of these tools for numerous vegetable crops can be confusing. This publication describes some of these tools and their advantages and disadvantages, based on four years of research at Cornell University. It should be noted, however, that this is not a complete list; several other designs are available that were not tested in these trials.

Flex-tine harrows

Flex-tine harrows are used broadcast, both over and between the crop rows. They are most efficient when weeds are in the white-thread or cotyledon development stage. In direct-seeded crops, such as snap beans or sweet corn, flex-tine implements are used preemergence. Tines pass above the planted seed. Harrowing can be repeated postemergence for control of newly germinated weeds, but only when the crop is well-rooted. Cultivation intensity can be modified to minimize crop damage. Guide wheels and tine intensity regulate harrowing depth.

Advantages

- Tools are available in large widths (up to 40′) and are operated at high speeds when used preemergence.

- Flex-tine implements are useful for a number of crops and row spacings with little or no equipment modifications.

- Tines that pass over the crop row can be lifted, allowing for aggressive between-row harrowing when the crop is sensitive to cultivation damage.

- Preemergence harrowing breaks crusted soils and may increase crop emergence rates.

Disadvantages

- Cultivation timing is critical; weeds with four or more leaves and emerged grasses at any stage are rarely controlled. Therefore, early-season flex-tine harrowing should be integrated with a more aggressive cultivator or with postemergence herbicides for control of escaped or newly-germinated weeds.

- Research in transplanted broccoli, snap beans and sweet corn has shown that flex-tine harrows can reduce crop stand and yield when used before the crop is well-rooted.

Implement descriptions

Einbock flex-tine harrow

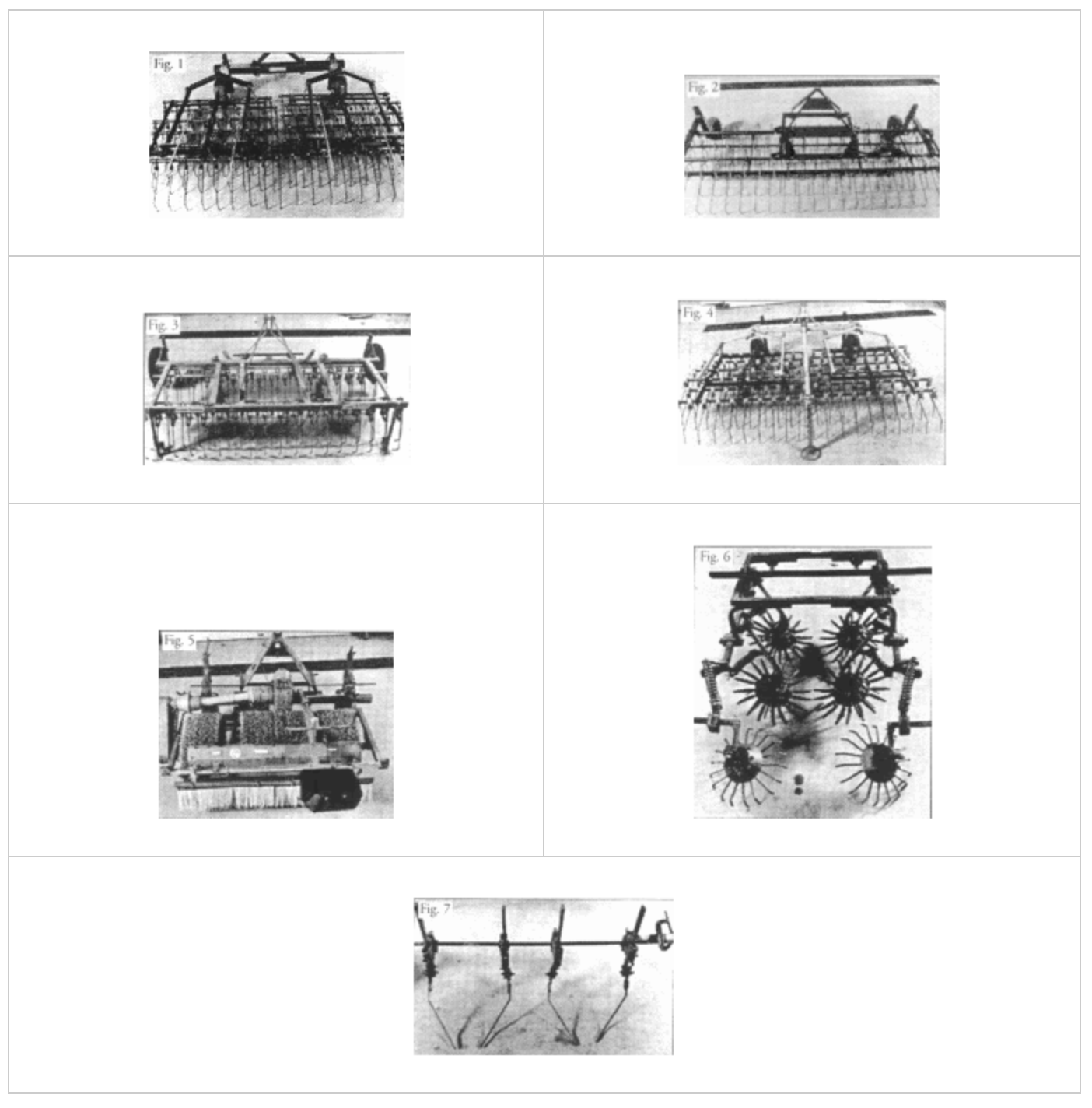

The Einbock harrow (Fig.1) has floating beds of tines mounted on a tool bar. Cultivation on uneven ground or hillsides is possible with the floating bed system. Tines can be lifted above the crop row; however, tine intensity is modified on a bed-by-bed basis with a single adjustment.

Lely flex-tine harrow

The Lely harrow (Fig.2) is a lightweight tool with very flexible tines that vibrate to rip weeds from the soil. The implement’s light weight can be a “cure or curse”–the harrow is easily maneuvered with a low-horsepower tractor, but its cultivation efficiency is reduced on hard-packed or crusted soils. Tine intensity is modified on a tine-by-tine basis.

Rabe Werk flex-tine harrows

Rabe Werk manufactures two harrows; on having flat tines (Fig.3) and one with round tines (Fig.4). The flat-tined harrow is very aggressive and effectively breaks crusted soils. Tines are modified individually in three intensities: high, low, and tines lifted above the crop rows. The round-tined implement is similar to the Einbock harrow and has floating beds of tines.

The Baertschi brush hoe

The brush hoe has PTO-driven plastic bristles that rotate on a horizontal plane, aggressively ripping weeds from the soil. (Fig.5) Shields, hung above the soil surface, protect the crop from the rotating brushes but allow soil to move into the crop row. Because the tool is very aggressive and precise, and additional operator (on the rear seat) is required to steer the shields over the crop row. Cultivation depth is modified with guide wheels and the three-point hitch attachment. Several row spacings and brush configurations are available.

Advantages

- The aggressive nature of the brush hoe increases the length of time available for effective cultivation; weeds up to ten inches tall can be controlled.

- The implement is effective on slightly moist soils.

- Soil passing under the shields smothers weeds in the crop row.

- The dust layer that results from brushing delays new weed germinations. For example, in transplanted broccoli, a single pass of the brush hoe provided season-long weed control comparable to standard herbicides without reducing yields.

Disadvantages

- The brush hoe requires two operators.

- Wind erosion is possible with aggressive brushing on dry soils.

- Row spacing modifications are expensive and time consuming; therefore, all cultivated crops must have the same spacing.

- The initial implement purchase is costly.

The Buddingh finger weeder

The finger weeder is designed specifically for in-row weed control (Fig.6). The tool has three pairs of ground-driven rotating fingers: two pairs in the front push soil and uprooted weeds away from the crop row; while the third pair pushes soil back into the row, covering weeds that were missed by the other fingers. The weeder is most effective when fingers pass very close to the crop row; therefore, precise cultivation and slow driving speeds are important. The finger weeder is most effective on small-acreage, high-value crops.

Advantages

- The weeder offers excellent in-row weed control.

- The finger weeder is a light weight tool and can be mid-mounted on a small tractor.

Disadvantages

- The weeder must be used when weeds are small; therefore, timing is critical.

- Between-row control is poor. Finger weeders should be used in combination with an inter-row cultivator.

- Slow, precise cultivation is necessary to minimize crop damage.

Bezzerides torsion weeder

The torsion weeder is mounted on an existing inter-row cultivator for improved in-row weed control (Fig.7). This simple tool has spring-loaded steel rods on each side of the crop row for undercutting small weeds. The width of the uncultivated strip is easily adjusted for each crop and development stage.

Advantages

- The torsion weeder offers excellent in-row weed control.

- The simple design minimizes potential cultivator repairs.

- The torsion weeder is an economical addition to an existing cultivator.

Integrated Management Strategies

The best weed control strategy often integrates several management strategies, which may include mechanical control Two ways to reduce herbicide use while minimizing the risk of poor weed control and reduced yields are to combine cultivation with banded herbicides or with some of the new postemergence herbicides (e.g. Reflex and Basagran for snap beans), used on an as-needed basis. Research in sweet corn, for example, has shown that yields were equivalent when a single cultivation was combined with Dual and Atrazine banded over the crop row and when the same herbicides were applied broadcast without cultivation, even in wet years. Results were similar in potato studies, where the combination of banded herbicides and a single hilling six weeks after planting produced yields equivalent to broadcast herbicides plus hilling.

Manufacturers

| Brush Hoe | Bartschi FOBRO 1715 Airpark Grand Haven, MI 49417 Phone: 616-847-0300 Fax: 616-842-1768 |

| Finger Weeder | Buddingh Weeder Co., 7015 Hammond Ave., Dutton, MI 49316 Phone: 616-698-8613 |

| Torsion Weeder | Bezzerides Brothers, Inc. 14142 Ave 416 Orosi, CA 93647 Phone: 559-528-3011 |

| Flex-Tine Harrows | Einbock | Landaschinenbau G.E.S. m.b.h. & Co. KGA-4751 Dorf an der Pram, Austria Phone: 43-7764-6466 Fax: 43-7764-65-3585 |

| Canadian Distributor HWE-Agricultural Tech. Ltd. Mr. Hans Evermann B.P. 1515 Cdn. Embrun, Ont. KOA 1WO Phone/Fax: 613-443-3386 |

||

| Rabe Werk | Machinerie Agricole St. Cesaire, Inc. C.P. 399, 650 Route 112 St. Cesaire, Qc JOL 1TO Canada Phone: 514-469-4081 Fax: 514-469-3659 |

|

| Lely | Lely Corporation Box 1060, US 301 South Wilson, NC 37894 Phone: 919-291-7050 Fax: 919-291-6183 |

Reprinted from IPM Fact Sheet 102FSNCT, a Cornell Cooperative Extension publication.

Jed Colquhoua and Robin Bellinder, Department of Fruit and Vegetable Science, College of Agriculture and Life Sciences, Cornell

Updated: T. Jude Boucher, UConn IPM, 2012

The information in this document is for educational purposes only. The recommendations contained are based on the best available knowledge at the time of publication. Any reference to commercial products, trade or brand names is for information only, and no endorsement or approval is intended. The Cooperative Extension System does not guarantee or warrant the standard of any product referenced or imply approval of the product to the exclusion of others which also may be available. The University of Connecticut, Cooperative Extension System, College of Agriculture and Natural Resources is an equal opportunity program provider and employer.